Product packaging is no longer just a visual layer, it directly impacts your brand reputation, customer trust, and long-term business growth. For manufacturers of bottled products, secure and smart packaging is non-negotiable. Your customers expect products that reach them safe, intact, and tamper-free.

Among the many packaging solutions available, holographic induction sealing wads stand out as one of the most reliable, secure, and widely used options across industries like FMCG, Pharma, Agro, and Automotive.

The Risk of Weak Packaging

Poorly packaged bottled products are highly vulnerable to:

- Leakage and spillage

- Counterfeiting and duplication

- Tampering and adulteration

Damaged or compromised products reaching consumers can lead to loss of trust, declining sales, and long-term brand damage. This is where secure induction wads become essential.

What Are Holographic Induction Sealing Wads?

Holographic induction sealing wads (also known as holographic wads or liners) are seals applied to the mouth/lip of bottles to create an airtight, leak-proof barrier. These wads not only protect the contents but also provide a high level of security against duplication and counterfeiting.

Key Functions

- Seal and protect product contents from moisture, bacteria, and contaminants

- Deter counterfeiting with advanced holographic patterns

- Enable digital product authentication

- Support track & trace and inventory management

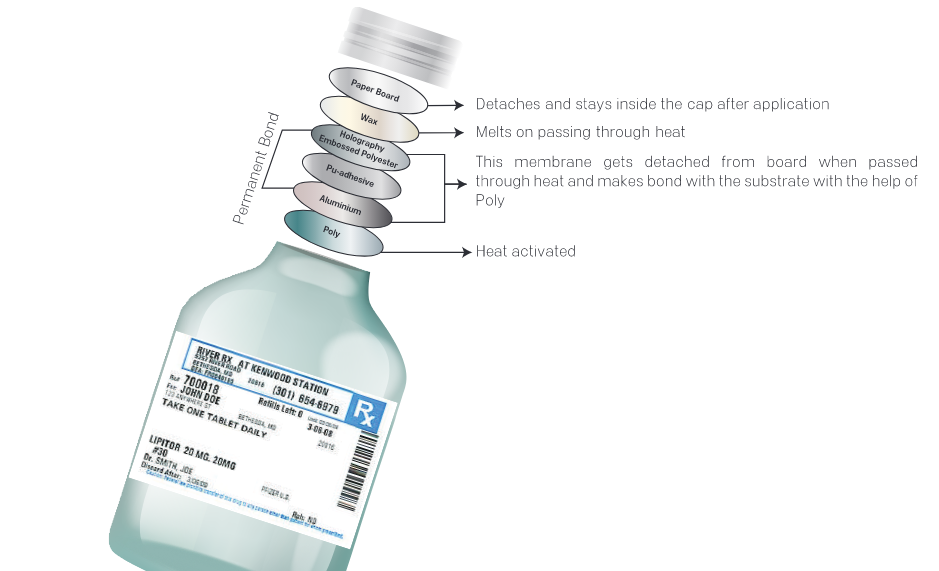

What Are Holographic Induction Wads Made Of?

Premium-quality induction wads typically include:

- Paperboard

- Wax

- Holographic film

- Aluminum foil

- Polymer layers

How Induction Sealing Wads Work?

During sealing, the cap lined with the induction wad passes under an electromagnetic field.

The aluminum layer heats up, melting the wax and bonding the seal permanently to the bottle rim, creating a tamper-evident and airtight closure.

The paperboard layer remains attached inside the cap.

Why Choose Holographic Wads Over Generic Wads?

Generic induction wads offer basic sealing but zero security. They can be copied easily—putting your brand and customers at risk.

Benefits of Holographic Wads

- Impossible to replicate due to advanced optical & nano-holography

- Provides high visual appeal with custom logos and branding

- Protects your supply chain from counterfeiters

- Enhances customer trust and brand authenticity

Smart Packaging: Integrating Holographic Wads with Digital Solutions

Holostik’s holographic wads can be integrated with printed QR codes, delivering powerful digital benefits:

Digital Capabilities

- Digital product authentication

- Track & Trace

- Supply chain visibility

- Loyalty and warranty programs

- Real-time data insights

- Inventory & raw material monitoring

This combination of physical + digital security makes holographic induction wads a truly phygital packaging solution.

Why Choose Holostik Holographic Induction Sealing Wads?

Holostik offers variants designed specifically for your product, environment, and industry needs.

Strong Leak-Proof & Pilfer-Proof Sealing

Ensures product contents remain intact and safe.

Advanced Anti-Counterfeiting Holography

Deters duplication and protects your brand identity.

Tamper-Evident Protection

Consumers can instantly identify tampering.

QR-Integrated Smart Wads

Supports product authentication, track & trace, and digital supply chain management.

Available Wads Variants

- Holographic Wads

- Printing on Chromo Paper

- Wads with Printing on Aluminium

- Registered Holographic Wads

Get Secure, Smart, and Customizable Induction Sealing Wads

Holostik is one of India’s leading induction wads manufacturers, offering high-quality holographic sealing solutions for diverse industries.

📞 Call us: 9905-124-124

📩 Mail us: marcom@holostik.com

FAQs on Holographic Induction Sealing Wads

1. What are holographic induction sealing wads?

2. How do holographic wads help prevent counterfeiting?

3. Are holographic wads better than normal induction wads?

4. Can holographic induction wads include QR codes or digital features?

5. Which industries use holographic induction sealing wads?